Products

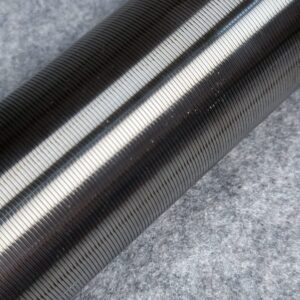

Customized Gear Shaft

It is precisely made of high-strength steel and features excellent wear resistance and impact resistance. Precision processing technology ensures the accurate meshing of gear shafts, achieving smooth rotation and low-noise operation. Its optimized design makes power transmission more efficient and reduces energy loss. It is applicable to a variety of industrial fields and provides reliable operation support for equipment. The long-lasting and durable performance ensures the long-term and stable operation of mechanical equipment.

Gear Shaft: Essential Features

Robust and Precise Design:

- The design of the gear shaft is engineered for high precision and strength, ensuring optimal performance in both industrial machinery and automotive applications where reliability under stress is crucial.

- Constructed using high-quality materials such as alloy steel, these shafts possess excellent durability, wear resistance, and longevity, key for maintaining consistent performance in demanding environments.

- Featuring advanced machining techniques, gear shafts are tailored for seamless integration with gear systems, providing smooth operational efficiency and reducing backlash, vital for high-speed machinery.

Advanced Technical Specifications:

- Gear shafts come in various configurations such as spur, helical, and bevel gears, each designed to cater to specific mechanical requirements and offering versatility in applications across industries.

- They are engineered with precision-ground surfaces and dimensional accuracy that ensures perfect alignment with gears, crucial for reducing vibration and noise during operation and extending component life.

- Enhanced load-bearing capacities allow gear shafts to handle substantial torque and power transmission demands, essential for heavy-duty applications found in sectors like manufacturing and automotive engineering.

- Gear shafts provide reliable solutions across diverse sectors, supporting continuous improvements in machine efficiency and productivity which are vital for maintaining competitive supremacy.

- Their adaptability to varying machinery requirements ensures customized solutions that align with specific project demands, offering tailored applications across industries from automotive engineering to advanced robotics.

Cost-effectiveness and Innovation:

- With low-maintenance characteristics, gear shafts contribute to reduced total cost of ownership, presenting a cost-effective solution for industries requiring regular and efficient machinery operations.

- Their innovative design leverages state-of-the-art manufacturing techniques to improve performance while maintaining economic viability, essential for organizations focused on maximizing output while adhering to budget constraints.

- Engineered to meet the evolving demands of industrial systems, these shafts add value through sustainable operational practices, enhancing productivity while promoting environmentally-responsible engineering solutions.

Gear Shaft Applications

- Essential for automotive transmission systems, where they facilitate smooth gear shifting and power delivery, improving vehicle performance, fuel efficiency, and driving experience.

- Critical for industrial machinery, including construction equipment and manufacturing systems, where they play a pivotal role in power transmission, supporting operational effectiveness and system integrity.

- Their precision engineering makes them suitable for technology-driven solutions where accuracy and reliability in motion control systems are necessary, such as in robotics and aerospace engineering.