Products

Coal Mine Concrete Pump

Coal mine concrete pumps are specially designed for underground mining environments to ensure trouble-free operation under harsh conditions. Equipped with a powerful hydraulic system, it can effectively transport high-viscosity concrete and support long-distance pouring.

The optimized structural design enhances equipment stability, reduces maintenance costs and downtime.

Concrete Pumps for Coal Mines/Split Type: Features and Advantages

Perfectly suited for reinforcing critical underground structures such as tunnels, shafts, and passageways, these pumps play an integral role in ensuring the structural integrity of coal mining infrastructure.

They are particularly effective for emergency repair scenarios, providing rapid concrete deployment in areas experiencing high environmental stress or where potential structural collapses may occur, offering a reliable solution for crisis management.

Their design requires minimal maintenance, which translates into reduced upkeep costs for operators and owners while maintaining operational readiness and dependability.

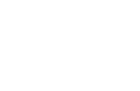

Concrete Pumps for Coal Mines/Split Type Technical Specifications:

Outfitted with advanced hydraulic systems, these pumps provide exceptional pumping capabilities, ensuring a steady and reliable concrete delivery even in extreme underground mining scenarios.

They offer a range of output capacities, making them highly versatile and suitable for different scales of mining projects, ranging from small localized tasks to large-scale infrastructure undertakings.

Designed with cutting-edge safety features, these pumps prioritize the protection of operators and machinery, which is crucial in environments susceptible to operational hazards.

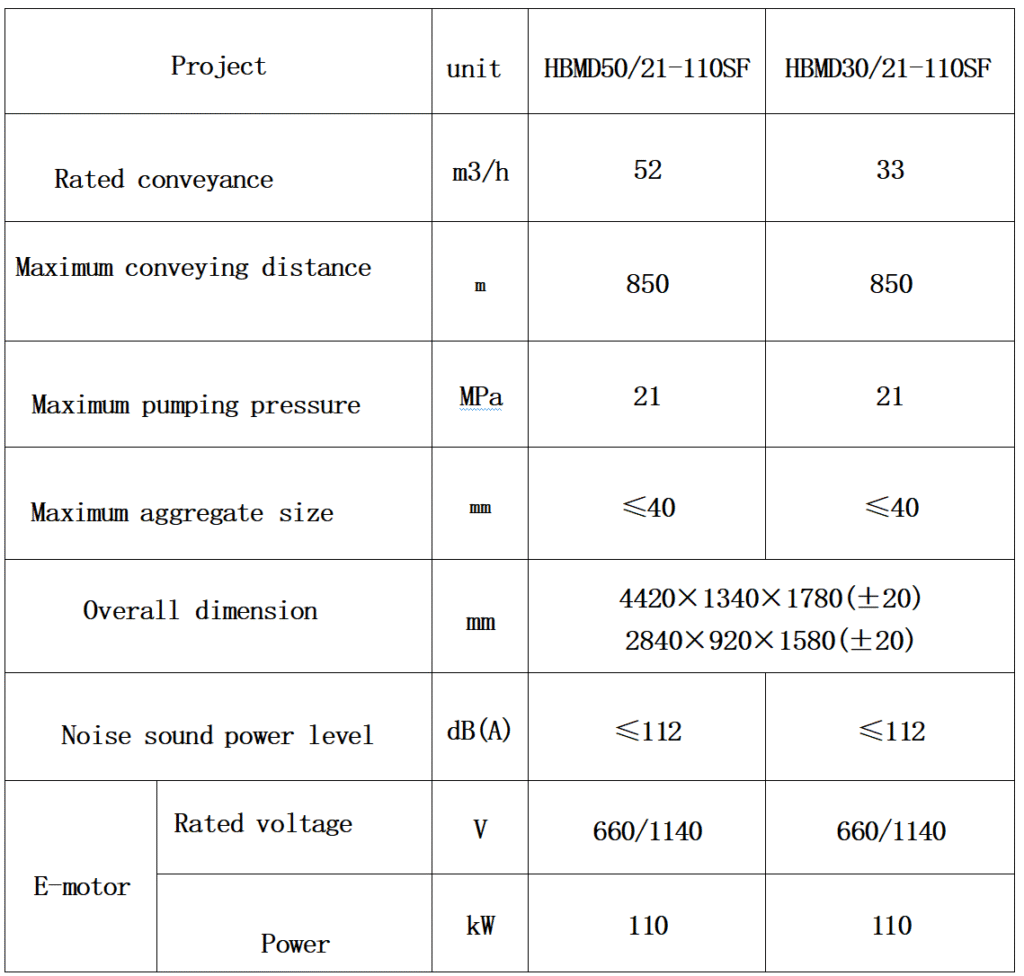

Coal Mine Concrete Pump Integrated type:Features and Advantages

They seamlessly combine all necessary components into a single unit, maximizing space efficiency and reducing installation time, crucial for urgent mining projects that demand quick deployment.

Engineered to endure the challenging conditions of coal mines, these pumps exhibit high durability and operational resilience, ensuring consistent performance without frequent maintenance interruptions.

Their design emphasizes low maintenance, enabling sustained operational readiness without incurring high upkeep costs, maximizing project profitability and operational efficiency.

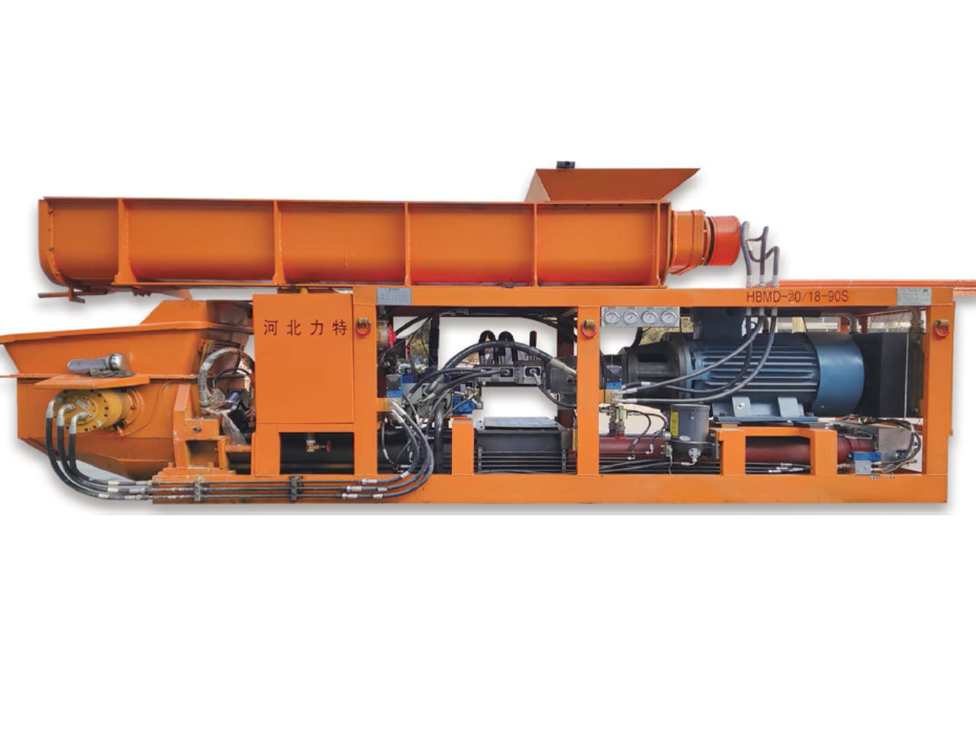

Coal Mine Concrete Pump Integrated type Technical Specifications:

Integrated pumps are valuable for quick-response maintenance and repair operations in areas susceptible to environmental stress or structural instability, providing critical support in maintaining operational integrity.

Their compact design allows them to work seamlessly alongside other mining equipment, creating a cohesive system that enhances construction efficiency, reduces setup time, and improves workflow execution.

Known for their reliability and durable construction, these pumps are engineered using high-quality materials that ensure operational longevity, reducing the need for frequent repairs.

Coal Mine Concrete Pump: Industry Applications

- Underground Infrastructure:

- Shaft Lining: Steel fiber-reinforced concrete pumping (80 mm aggregate) for main shaft stabilization (ASTM C1116).

- Roadway Support: Shotcrete application (wet-mix) for rib and roof bolting (≥50 MPa compressive strength).

- Emergency Reinforcement:

- Rockfall Sealing: Rapid-setting grout injection (≤15 min cure time) for collapsed tunnel repair.

- Fireproof Barriers: Vermiculite-based concrete spraying to isolate spontaneous combustion zones.

- Ventilation & Utilities:

- Sealing Ducts: Pumpable foam concrete (density 800 kg/m³) for air leakage control in ventilation shafts.

- Pipeline Encasement: Non-shrink mortar pumping around gas drainage pipes (EN 445/446).

- Surface Mining Integration:

- Batching Plant Feed: Continuous pumping to overland conveyors for slope stabilization grids.

- Tailings Dam Construction: High-volume pumping (120 m³/h) of fly ash concrete for embankment lining.