Products

Oilfield Custom Gearbox

Material: 304/316 Stainless Steel

Process: Photochemical Etching Technology

Pattern Options: Customizable (Geometric/Organic/Digital)

Thickness Range: 0.1mm-2.0mm (±0.02mm)

Finish: Satin/Mirror/Color Coated

Application: Architectural Cladding/Decorative

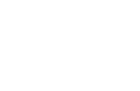

What is the Etched Metal Mesh?

Our Etched Metal Mesh is a precision-engineered perforated material manufactured through advanced photochemical or laser etching processes on high-grade stainless steel (AISI 304/316), brass, or aluminum substrates (0.05mm–3mm thickness). Utilizing photolithography masking (resolution down to 10µm) and controlled acid baths (HNO3/HF-based, ISO 9001:2015 compliant), it achieves intricate patterns with ±0.02mm dimensional accuracy and burr-free edges (Ra ≤0.8µm per ASTM B881).

The process creates aperture sizes from 0.1mm to 20mm, with open area ratios of 5%–80% and tensile strengths up to 800 MPa (ISO 6892-1). Post-etching treatments include electropolishing (ASTM B912) for hygienic surfaces or anti-reflective coatings (MIL-C-675C) for optical applications. Certified to RoHS, REACH, and IPC-4552A standards, it delivers EMI shielding effectiveness up to 120 dB (1–10 GHz per MIL-STD-285).

Why Choose Our Etched Metal Mesh?

- Micro-Precision: Achieve complex geometries (hexagonal, radial, custom CAD patterns) with 99% repeatability and zero mechanical stress.

- Corrosion Resistance: Passivated 316L variants withstand 5,000+ hours in salt spray (ASTM B117) and pH 1–14 environments.

- Lightweight Durability: 50% weight reduction vs. stamped meshes, maintaining 400 MPa yield strength (EN 10088-2).

- Aesthetic Versatility: Brushed, mirror, or color-coated finishes (RAL/Pantone-matched) for architectural integration.

- Thermal Stability: Operates from -200°C to 650°C (Inconel 600 versions) without warping or oxidation.

Etched Metal Mesh Manufacturing Precision & Quality Control

Our Etched Metal Mesh undergoes a rigorously controlled production process compliant with ISO 9001:2015 and IATF 16949 automotive standards. Utilizing aerospace-grade photochemical etching (tolerance ±0.015mm), we deploy high-resolution photomasks (20,000 DPI resolution) and proprietary etchant formulas (pH-controlled to ±0.1) to achieve zero HAZ (Heat-Affected Zone) and <2µm edge roughness. Each batch undergoes 3-stage QA:

- Pre-Production: Material certification (ASTM E1479 metallurgical analysis) and sheet flatness verification (<0.1mm/m² deviation).

- In-Process: Automated vision inspection (5MP CCD cameras) for pattern fidelity at 50x magnification (IPC-A-610 Class 3).

- Post-Treatment: Salt spray testing (ASTM B117 for 1,000+ hours) and tensile strength validation (ISO 6892-1 Method A).

Galvanized Wire Mesh Applications

- Electronics: EMI/RFI shielding gaskets (IEC 61000-4-3 compliant) for 5G enclosures and aerospace avionics.

- Architectural Facades: Daylighting panels with 70% UV filtration (EN 410) and parametric design flexibility.

- Medical Devices: Sterilizable surgical instrument filters (ISO 13485) with 0.2µm microbial retention.

- Automotive: Cabin air intake grilles (SAE J1128) and EV battery thermal management screens.

- Industrial Filtration: Sieve plates for pharmaceutical granulation (USP <788> standards) and oil/water separation.